Exploring Traditional Fasteners | Zips

We all use them in our daily lives, but just how much do we really understand about zips or do we just take them for granted?

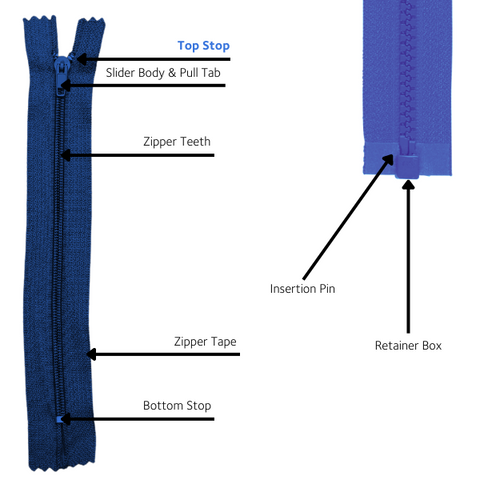

The components of zips

| Top Stop | Bottom Stop |

This is a small bar that sits at the top and it stops the slider from coming off the top of the zipper tracks. |

As the name may well suggest, this is a bar at the bottom that acts the same as a top stop but is at the bottom of the zipper tracks. |

| Slider Body | Pull Tab |

|

|

| Zipper Tape | |

|

|

Components of Separating Zips only |

|

| Retainer Box | Insertion Pin |

|

|

The different zip types

Now you know all about the anatomy of a zip, it’s time to take a look at the different types of zips that exist. The most common of these are:

- Closed-end zips

- Open-end zips

- Two-way zips

- Continuous chain

Let’s take a look at these in turn:

|

Closed-end zipsFor anyone who may be unfamiliar with working with, and sewing, zips, closed-end zips are the place to start. Why? Well, they’re incredibly easy to get to grips with. You’ll find that this type of zip has a bottom stop. As we have seen, this is a metal bar that goes across the bottom of the zipper and acts to hold it together in one piece. |

|

Open-end zipsOpen-end zips are also sometimes referred to as separating zips. As the name suggests, this kind of zip separates at the bottom. These are the best choice when it comes to fastenings that require opening and closing. You’ll find that open-end zips are commonly used in jackets and coats. |

|

Two-way zipsTwo-way zips do just what their name suggest: they work two ways. This means that they can be closed, or opened from either end. These are great for flexibility and also security as the zips can be padlocked together. You’re most likely to come across two-way zips on the likes of backpacks and suitcases. |

|

Continuous chainThese are zips that have no beginning or end. Continuous chain can be cut to the length that’s required. The fact that there’s no pull tab or bottom stop means that you get to purchase the zipper tape by the metre. If using continuous chain, zip pulls are something that will need to be bought separately. The advantages of continuous chain are that users have great control over the appearance and they are perfect for when long zips are needed. |

The materials used for zips

Whether you’re looking at continuous chain, open-end zips or any of the other types, you will find that these are made in a variety of ways, using a variety of materials. The most common of these include:

- Nylon coil zips

- Plastic moulded

- Metal zips

- Invisible zips

Next, we’ll take a look at each of these in turn:

Nylon Coil Zips These types of zips have the teeth made from nylon rather than the likes of plastic or metal. It’s made from nylon monofilament which is then coiled before being woven or stitched into the zipper tape. These nylon teeth are perhaps the most flexible type and they’re extremely popular when it comes to luggage, tents and jackets. The popularity stems from the fact that they are extremely strong as well as being easily repairable. |

Plastic Moulded Zips Moulded plastic zips are commonly made from acetal polymer plastic. They feature symmetrical teeth that interlock. When compared to other zip types, they tend to have more defined and substantial teeth. This leads to them being referred to as ‘chunky’. You’ll usually find these zips being used on handbags and clothes, such as jackets. The downside with these zips is that they can be difficult to fix should they be broken. |

Metal Zips With teeth made out of metal, this zip type is probably the most sturdy, as well as being the most durable. Potential downsides here can be the weight of them and the fact that they’re harder to shorten and work with generally. One of the reasons that they tend to be used on the likes of jeans is because they are highly resistant and are capable of withstanding numerous washes without becoming damaged. |

Invisible Zips Also known as concealed zips, these are designed to be practically invisible. You’ll find that these types of zips have extremely fine teeth and, to go a fine finish, there usually sewn into the seam in garments. If they’re fitted correctly, you should only be able to see the pull tab. These zips are largely used in dressmaking in instances when the designer does not want the zip to be visible from the outside of the garment.

|

We’ve got you covered

No matter what you need from your zips, you can be sure that we have the solution.

Why not check out our range here and, if you have any queries just get in touch and we’ll be happy to help.

Efficient Production

Lean manufacturing methods and extensive stock holding capabilities. You can rely on us.

Compliant & Certified

All products and processes are subjected to rigorous quality checks. You can trust us.

Customisable Products

Looking for a bespoke product to suit your exact requirements? Just ask us.